Unlocking Efficiency and Excellence: The Power of an Automatic Rice Mill

In today’s competitive agricultural landscape, efficiency, consistency, and product quality are paramount. For rice millers in India and across the globe, the move from traditional methods to advanced automation is no longer a luxury but a necessity. This is where the Automatic Rice Mill comes into play – a comprehensive, intelligent system designed to transform raw paddy into perfectly polished rice with minimal human intervention.

At Ricetec Machinery, we are at the forefront of this technological revolution, providing state-of-the-art automatic rice mill solutions that empower businesses to achieve higher yields, superior quality, and greater profitability.

What Defines an Automatic Rice Mill?

An automatic rice mill is much more than just a collection of machines; it’s a sophisticated, integrated processing plant where every stage of rice milling is interconnected and controlled by a central system. Unlike manual or semi-automatic setups that require continuous human oversight and material handling between stages, an automatic mill operates seamlessly, ensuring a continuous flow from paddy intake to bagged finished rice.

Key characteristics that set an automatic rice mill apart:

- End-to-End Integration: All core processing stages are linked, creating a continuous production line.

- Minimal Human Intervention: Operators primarily monitor the system via control panels, manage adjustments, and oversee quality checks, significantly reducing manual labor.

- Precision and Consistency: Advanced sensors, automated controls, and pre-set parameters ensure uniform processing, leading to consistent product quality and reduced variability.

- High Throughput and Productivity: Designed for large-scale operations, these mills can process significant volumes of paddy per hour, maximizing output.

- Centralized Control System (PLC): Often equipped with a Programmable Logic Controller (PLC) system, offering real-time data, remote monitoring capabilities, and simplified operation management.

The Journey of Rice in an Automatic Mill: A Step-by-Step Overview

An automatic rice mill meticulously guides the paddy through a series of specialized machines, each designed to perform a specific function with optimal precision:

-

Paddy Receiving and Pre-Cleaning:

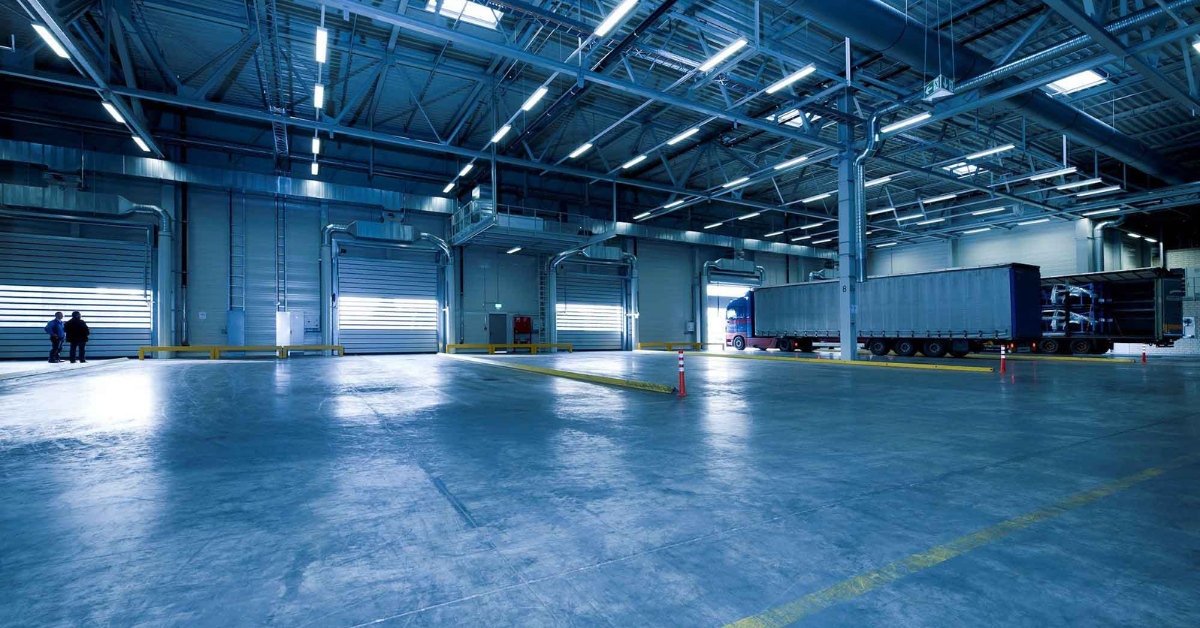

- Paddy Intake Pit: The starting point where raw paddy is unloaded.

- Pre-Cleaner: Employs vibrating screens and aspiration to remove coarse impurities like straw, leaves, strings, and larger debris.

- De-Stoner: Separates stones and other heavy foreign materials from the paddy using a combination of vibration and airflow, crucial for protecting downstream machinery.

- Aspiration System/Dust Collector: Integrated throughout the plant to capture and remove lighter dust and chaff, ensuring a clean processing environment and pure product.

-

Hulling Section:

- Paddy Husker (Sheller): This is where the outer husk (hull) is efficiently removed from the paddy grain, typically using rubber rollers. The design prioritizes minimizing damage to the brown rice kernel.

- Husk Aspirator: Utilizes air currents to separate the light husks from the mixture of brown rice and unhusked paddy.

-

Paddy Separation:

- Paddy Separator: A critical machine that meticulously separates the output from the husker into three distinct streams:

- Unhusked paddy (recycled back to the husker for re-processing).

- Brown rice (ready for whitening).

- Any broken paddy (sent to the grading section).

- Paddy Separator: A critical machine that meticulously separates the output from the husker into three distinct streams:

-

Whitening Section:

- Rice Whitener (Milling Machine): This is where the bran layer is gradually removed from the brown rice, transforming it into white rice. Automatic mills often employ multiple stages of whiteners to achieve optimal bran removal with minimal stress on the grains, ensuring a higher yield of whole rice.

-

Polishing Section:

- Rice Polisher (Silky Polisher/Mist Polisher): The final touch for aesthetic appeal. This machine buffs the surface of the whitened rice, removing any remaining fine bran particles and imparting a smooth, glossy, and translucent finish. Mist polishers achieve a superior “silky” texture by introducing a fine mist of water, which helps in creating a fine, lustrous coating on the grain.

-

Grading and Sorting:

- Rice Grader: Separates the milled rice into various categories (e.g., whole rice, large broken, medium broken, small broken) based on length and thickness using vibrating screens or rotating cylinders.

- Color Sorter: An advanced optical sorting machine that uses high-resolution cameras and precision air ejectors to identify and remove discolored grains, chalky grains, immature kernels, and any minute foreign materials. This significantly enhances the purity, consistency, and market value of the final product.

-

Weighing and Packaging:

- Automatic Weighing and Bagging Machine: Precisely weighs the finished, graded rice and fills it into bags, which are then automatically stitched and sealed, ready for market.

-

Conveying Systems:

- Throughout the plant, bucket elevators, screw conveyors, and belt conveyors efficiently and automatically transport paddy and rice between different processing stages, ensuring a continuous and seamless flow.

-

Central Control Panel:

- The brain of the operation. This sophisticated electrical panel, often incorporating a PLC (Programmable Logic Controller), allows operators to monitor the entire milling process, adjust parameters, troubleshoot issues, and collect valuable production data for optimization.

The Unmatched Advantages of an Automatic Rice Mill

Investing in an automatic rice mill offers a compelling return on investment and positions your business for success:

- Maximized Efficiency and Productivity: Achieve significantly higher throughput rates and consistent production volumes day after day.

- Superior Product Quality: Automated processes ensure uniform whiteness, excellent polish, minimized broken rice percentages, and exceptional purity, leading to premium market prices.

- Reduced Operational Costs: Automation dramatically lowers reliance on manual labor, resulting in substantial savings on wages and related expenses.

- Optimal Head Rice Yield: Precise control at each stage, especially in hulling and whitening, minimizes grain breakage, directly translating to higher revenue.

- Enhanced Hygiene and Safety: Enclosed systems and efficient dust collection contribute to a cleaner, safer working environment and prevent product contamination.

- Energy Efficiency: Modern automatic mills are designed with optimized motor configurations and energy-saving features, reducing electricity consumption.

- Better By-Product Management: Efficient collection of husk, bran, and broken rice for their respective commercial uses (e.g., fuel, oil extraction, animal feed).

- Scalability and Competitiveness: Allows businesses to easily meet increasing market demand, diversify product offerings, and gain a significant competitive edge in the domestic and international rice markets.

- Data-Driven Optimization: PLC-controlled systems provide valuable production data, enabling continuous process improvement and operational optimization.

Partnering with Ricetec Machinery for Your Automatic Rice Mill

At Ricetec Machinery, we are committed to empowering rice millers with cutting-edge technology. Our automatic rice mill solutions are engineered to deliver unparalleled performance and reliability. We offer:

- Customized Project Planning: Tailored plant designs to match your specific capacity requirements, available space, and budget.

- High-Quality, Durable Machinery: Manufactured using robust materials and precision engineering for long-lasting operation and minimal maintenance.

- Seamless Integration: Expertise in ensuring all components work in perfect harmony for optimal efficiency.

- Energy-Efficient Designs: Solutions that prioritize reducing your operational costs.

- Comprehensive Support: From initial feasibility studies and detailed project reports to professional installation, commissioning, operator training, and dedicated after-sales service.

Choosing an automatic rice mill from Ricetec Machinery isn’t just buying equipment; it’s investing in a strategic partnership that ensures the success, sustainability, and growth of your rice milling enterprise in the dynamic Indian and global markets.