Essential Guide to Galley Equipment: Enhancing Efficiency and Safety in Your Kitchen

When it comes to running a professional kitchen, whether on a commercial vessel, restaurant, or catering service, having the right Galley Equipment is crucial. Galley equipment refers to the specialized tools, appliances, and fixtures designed to optimize cooking, storage, and food preparation in confined spaces like ship galleys or small kitchens. This equipment not only boosts operational efficiency but also ensures safety and compliance with maritime or commercial kitchen regulations. In this comprehensive guide, we will explore everything you need to know about galley equipment — from its types and benefits to maintenance tips and frequently asked questions. Whether you are outfitting a new kitchen or upgrading your existing setup, understanding galley equipment will help you make informed decisions that save time, reduce costs, and improve overall kitchen performance.

What is Galley Equipment?

Galley equipment encompasses all the cooking, refrigeration, storage, and cleaning appliances used in a galley, the term often used for kitchens on ships or other compact, mobile environments. Unlike standard kitchens, galleys require specialized equipment that can function effectively in limited spaces and sometimes under challenging conditions such as motion and humidity. Common examples of galley equipment include cooking appliances (ovens, stoves, fryers), refrigerators and freezers, food preparation tools (mixers, slicers, cutters), storage units (shelves, racks, containers), ventilation systems, and dishwashing equipment. The design of galley equipment typically emphasizes durability, safety, and compactness, catering to the unique needs of maritime or commercial food service operations.

Types of Galley Equipment

Understanding the variety of galley equipment helps in selecting the right tools for your kitchen’s needs. Here are the primary categories:

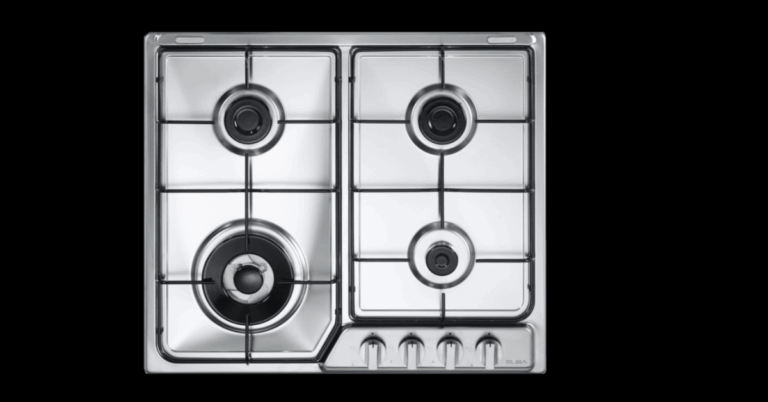

1. Cooking Appliances

Cooking appliances are the heart of any galley. These include gas or electric stoves, convection ovens, microwaves, and deep fryers. Marine-grade cooking equipment is often designed to withstand motion and limited ventilation, with features like secure mounting and flame failure devices.

2. Refrigeration Units

Galley refrigeration is essential for food safety and storage. Compact refrigerators, freezers, and cold storage lockers maintain the freshness of perishable goods. Marine refrigeration units are often energy-efficient and resistant to corrosion.

3. Food Preparation Tools

Equipment like mixers, food processors, meat slicers, and cutting boards assist in efficient food preparation. In galleys, these tools are designed to maximize counter space and ensure easy cleaning.

4. Storage Solutions

Shelving units, dry storage cabinets, and food containers are essential for organization. Space optimization is critical in a galley, so equipment that offers multiple functions or stackability is preferred.

5. Dishwashing and Cleaning Equipment

Automatic dishwashers and sinks with secure fittings help maintain hygiene standards. Cleaning supplies and waste disposal systems are also part of galley equipment, designed for efficiency in tight spaces.

Why Investing in Quality Galley Equipment Matters

The right galley equipment significantly impacts kitchen operations in various ways:

Safety

Marine and commercial kitchens face unique safety challenges, such as movement and confined spaces. High-quality galley equipment is built with safety features like anti-slip surfaces, flame arresters, and secure installations to prevent accidents.

Efficiency

Efficient equipment reduces preparation time, minimizes waste, and optimizes space utilization. This leads to smoother workflows and faster service delivery, which are vital in busy environments.

Durability

Galleys endure harsh conditions, including humidity, salt air, and constant use. Investing in robust, corrosion-resistant equipment ensures longevity and reduces replacement costs.

Compliance

Regulations for maritime and commercial kitchens are strict, focusing on hygiene and safety standards. Certified galley equipment helps operators meet these legal requirements without hassle.

Key Features to Consider When Choosing Galley Equipment

When selecting galley equipment, consider the following factors to ensure you get the best fit for your needs:

Space Constraints

Measure available kitchen space carefully. Choose compact, multi-functional equipment to maximize usability without overcrowding.

Power Source

Determine whether your galley uses gas, electricity, or both. Some equipment is dual-fuel capable, providing flexibility.

Material Quality

Opt for stainless steel or marine-grade materials for corrosion resistance and easy cleaning.

Energy Efficiency

Energy-efficient appliances reduce operating costs, especially important on vessels where power resources may be limited.

Ease of Maintenance

Look for equipment with removable parts and accessible panels to facilitate routine cleaning and servicing.

Maintenance Tips for Galley Equipment

Proper maintenance extends the life of your galley equipment and keeps it operating at peak performance. Here are some essential tips:

-

Regular Cleaning: Clean surfaces and internal parts daily to prevent buildup of grease and food particles.

-

Inspect for Wear and Damage: Check seals, hinges, and electrical connections regularly for signs of wear.

-

Lubricate Moving Parts: Apply appropriate lubricants to hinges, wheels, and motors as per manufacturer instructions.

-

Schedule Professional Servicing: Arrange periodic inspections by qualified technicians to identify and fix issues early.

-

Use Correct Cleaning Agents: Avoid harsh chemicals that can damage finishes; use marine-approved cleaning products.

Benefits of Upgrading Your Galley Equipment

Upgrading galley equipment can have transformative effects on kitchen operations:

-

Improved Food Quality: Advanced cooking appliances provide consistent temperatures and better control.

-

Energy Savings: Newer models are often more energy-efficient, cutting down fuel or power consumption.

-

Enhanced Safety: Modern equipment incorporates updated safety features to protect staff.

-

Better Space Management: Slimmer, modular designs free up valuable space.

-

Compliance Assurance: Up-to-date equipment ensures compliance with evolving regulations.

Galley Equipment Trends to Watch

The galley equipment industry is evolving with technology and environmental awareness shaping new developments:

-

Smart Appliances: IoT-enabled equipment allows remote monitoring and automation, improving efficiency.

-

Sustainable Materials: Use of eco-friendly, recyclable materials reduces environmental impact.

-

Energy Recovery Systems: Innovative ventilation and cooking systems recycle heat to save energy.

-

Modular Designs: Customizable units that can be reconfigured based on changing kitchen needs.

-

Improved Safety Standards: Enhanced flame detection and suppression systems provide greater security.

Frequently Asked Questions About Galley Equipment

What makes galley equipment different from regular kitchen equipment?

Galley equipment is specifically designed for use in confined, often mobile environments like ships. It emphasizes durability, compactness, safety, and compliance with maritime or commercial kitchen regulations.

How often should galley equipment be serviced?

Regular servicing should be done at least once every six months, but high-use equipment may require more frequent checks. Daily cleaning and routine inspections by staff are also essential.

Can galley equipment be customized?

Yes, many manufacturers offer customizable options to fit specific space constraints and operational needs, including size, power source, and storage capacity.

What safety features are common in galley equipment?

Common safety features include flame failure devices, secure mounting systems, anti-slip surfaces, temperature controls, and ventilation safeguards.

How do I choose energy-efficient galley equipment?

Look for appliances with energy ratings, efficient insulation, and technologies like induction cooking. Energy Star-certified products are a good benchmark.

Is it necessary to use marine-grade materials in galley equipment?

For ship galleys, marine-grade materials like stainless steel are crucial to resist corrosion caused by saltwater and humidity, ensuring durability and hygiene.

Conclusion

Galley equipment plays an indispensable role in the smooth operation of any compact or commercial kitchen environment, especially those on ships or other mobile platforms. By carefully selecting the right equipment, maintaining it properly, and staying informed about industry trends, kitchen operators can ensure safety, efficiency, and compliance with regulatory standards. Whether outfitting a new galley or upgrading an existing one, investing in quality galley equipment translates into long-term benefits, including better food quality, energy savings, and operational reliability. Understanding the unique demands of galley environments and choosing equipment designed to meet those demands is the foundation of a successful kitchen operation. If you are interested in sourcing durable, efficient, and safety-compliant galley equipment tailored for your specific needs, exploring professional suppliers with marine and commercial kitchen expertise will be a key first step.